29.Jan 2026

The CH 52 Gripper Ensures Safe and Reliable Handling of Weldments

In many manufacturing operations, handling weldments is one of the most demanding parts of the work cycle. This is due to their weight, complex shapes, sharp edges, and the need for precise positioning during further processing.

Common Challenges in Handling Weldments

- Complex shapes and off-center center of gravity make safe gripping difficult.

- Sharp edges and large dimensions increase safety requirements.

- Requirement for precise positioning without uncontrolled load movements.

While welding itself is often largely automated today, subsequent handling of weldments remains a critical point affecting safety, ergonomics, and production flow.

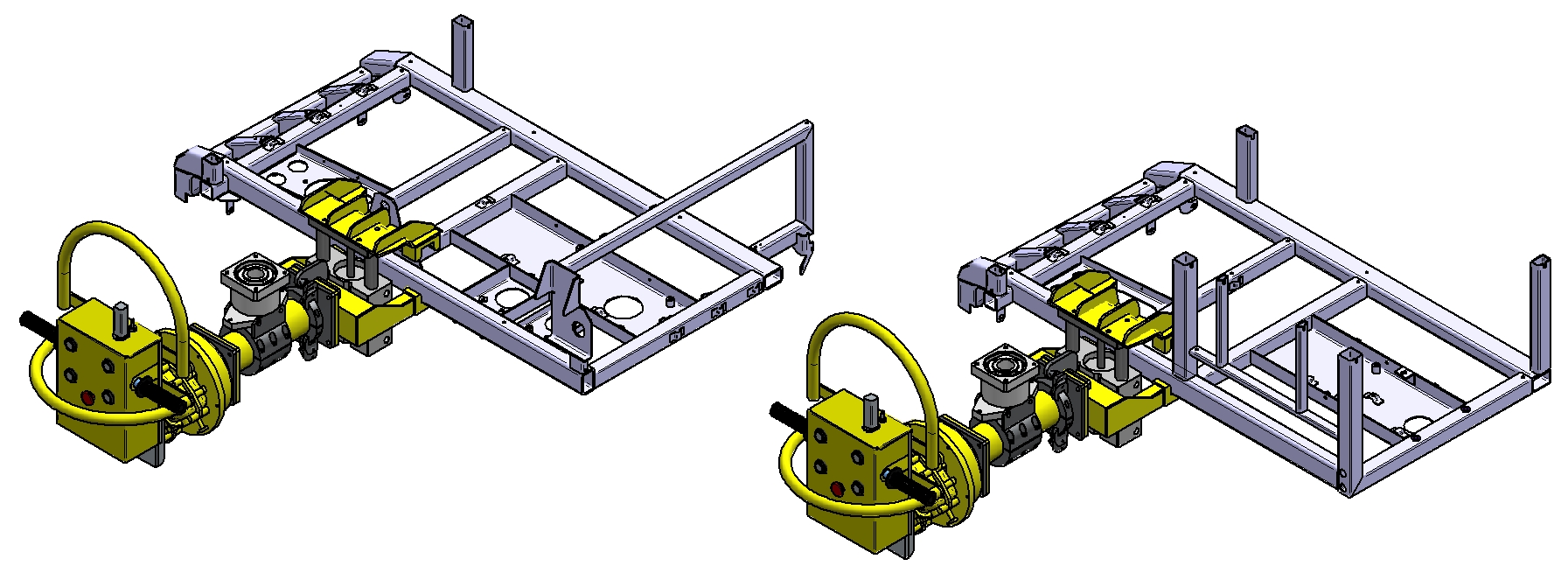

Weldment Gripper on a Two-Joint Manipulator with Telescopic Arm

The CH 52 gripper is specifically designed for handling weldments and functions as an active element of the handling system. It is intended for integration with a two-joint manipulator with a telescopic arm and an electrically driven hoist with frequency control. The result is comfortable, precise, and ergonomic handling of bulky weldments with minimal physical strain on the operator.

Basic Technical Parameters

- Type of work: handling weldments

- Gripper load capacity: max. 30 kg

- Own weight: 75 kg

- Dimensions: approx. 1100 x 650 x 500 mm

- Working air pressure: 0.55 – 0.6 MPa

Design and Components

During the design of this gripper, emphasis was placed on using components resistant to the abrasive environment of welding shops. Each part of the assembly is chosen for long service life and minimal planned maintenance requirements.

Main structural components:

- rotating hub

- carrying tube sleeve

- carrying tube

- support shaft

- bearings

- control panel

- pneumatic cylinder with guide

- rotary pneumatic drive (KINETROL – fixed jaw frame, pressure jaw frame).

Principle, Function, and Control of the Gripper

The gripper is equipped with a pneumatic system using FESTO / PNEUMAX / KINETROL components, which allows clamping and releasing the load in the gripper jaws and rotating the jaws. These are top-quality components from market leaders. The pneumatic drive operates at a working pressure range of 0.55–0.60 MPa. Correct operation of the gripper is ensured by pneumatic circuitry according to diagram no. CH.52.P.00.00.

The manipulator’s control interface is designed for natural operator movements. The control panel is located in the operator’s accessible zone and includes the following functions:

- Raising and lowering the load is performed via rotary handles, allowing smooth and precisely dosed vertical movement.

- Moving the load within the handling area is done by pulling or pushing the handles, or using the grip, without requiring excessive physical force.

- Clamping and releasing the load is controlled by buttons on the front of the control panel.

- Rotating the load is also managed by buttons on the front panel, allowing controlled changes of the load orientation during handling.

Two Positions, Two Usage Modes

The CH 52 gripper is designed to cover two different handling applications without the need for tool changes or modifications to the work process.

Removing a weldment from a welding positioner

The jaws are rotated with the fixed jaw facing down. The gripper segments engage the rectangular profile of the weldment from below, ensuring stable and unambiguous gripping.

Picking up a weldment from a grinding table

The jaws are rotated with the movable jaw facing down. It engages the profile from above, allowing safe removal of the part without manual position adjustment.

This flexibility improves production flow, reduces handling time, and lowers physical strain on the operator.

Safety and Control

The gripper is designed with emphasis on simple yet safe operation. An important safety feature is the requirement to press two buttons simultaneously when clamping or releasing the load, preventing accidental activation of the gripper. This protects the operator from unintended consequences due to inattention.

From a safety perspective, the system complies with standard requirements for equipment of this type.

Benefits of Using the Weldment Gripper in Operations

- Increased workplace safety and reduced risk of injury when handling weldments.

- Improved ergonomics even in complex positions.

- Repeatable and controlled movements limit manual improvisation during handling.

- Easy integration into material flow control systems.