15.Aug 2025

Manipulation Technology in Practice: When a Simple Manipulator is Better than a Robot

In today's era, where we constantly hear about robots, artificial intelligence, and autonomous systems, it might seem that classic manipulation equipment is already obsolete. However, this may not be entirely true. For a large portion of companies, column manipulators and systems on travel tracks represent the most practical and cost-effective solution for handling heavy loads.

Reality vs. Marketing: What Companies Actually Need

Media space is filled with news about advanced robotic systems and fully automated warehouses. In reality, however, most manufacturing companies need something completely different - reliable, simple, and affordable solutions for daily material handling.

Typical situation: a manufacturer needs to move 50-100kg components between workstations, load products into carts, or operate a production line. In such cases, investing in a robotic system worth several million would be unnecessary and often counterproductive.

Why Manipulators Win Over Robots

Simplicity and Reliability

A classic manipulator has several basic mechanical components. Robots, on the other hand, have hundreds of electronic elements and sensors. They can also contain a large number of various software modules. The math is simple in this case - the fewer components, the less can go wrong.

Example from practice: a manipulator on a travel track runs in three-shift operation for years without major problems. A robotic system requires regular software updates, sensor calibration, specialized service, etc.

Immediate Return on Investment

A column manipulator typically pays for itself within 6-18 months. A robotic system needs 3-5 years just to cover acquisition costs, let alone operating costs.

Real numbers: a manipulator costing 800 thousand saves annually 1.2 million in wage costs and reduced accident rates. A robot costing 4 million with the same function needs at least double the time for return on investment.

Flexibility Without Programming

Production program change? With a manipulator, it's enough to readjust mechanical stops or just relocate the working tool. With a robot, you need a programmer, new trajectories, and often changes to safety systems.

When Manipulators Are the Best Choice

Heavy Load Handling (50-1000 kg)

The heavier the load, the more the advantages of mechanical systems show. A manipulator can carry several tons without problems. A robot with similar load capacity would cost an astronomical sum.

Repetitive Operations with Variability

If you need to handle similar but not identical parts, a manipulator on a travel track can handle a wide spectrum without reprogramming.

Harsh Environment

Dust, humidity, vibrations, temperature fluctuations - classic manipulators tolerate all of this much better than sensitive robotic systems.

Limited Budget

A manipulator provides 80% of robotic system functionality for 20% of the price. For most applications, this is the optimal ratio.

Safety and Ergonomics - Main Arguments

Employee Protection

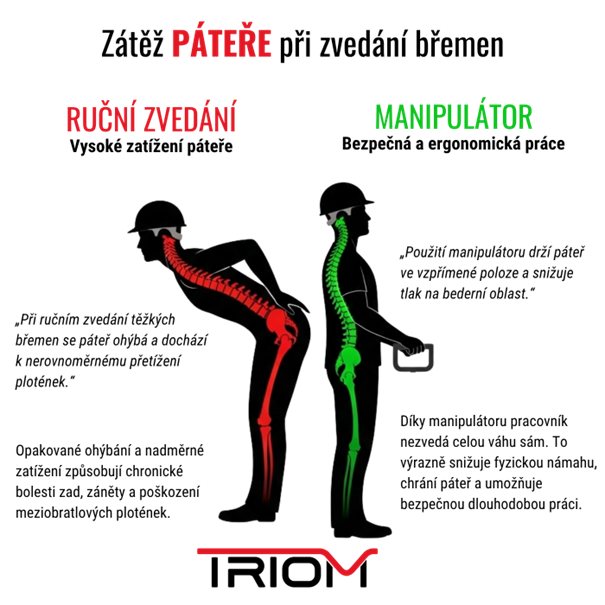

Every day we see workers struggling with heavy parts, bending in inappropriate positions, straining their spine and joints. A manipulator solves this problem immediately and definitively.

Statistics speak clearly: load handling causes the largest portion of all workplace injuries: According to the official SÚIP/ČBÚ report for 2023, the most frequent source of workplace injuries was the category "Materials, loads, products, machine components" (i.e., most material handling), where the share of total work incapacity was 32%. One properly placed manipulator can eliminate dozens of risky situations daily. [Source: State Labour Inspection Office, Indicator of OSH Level in Czech Republic – Evaluation of Work Accident Rates]

Legal Responsibility

The Labor Code clearly sets employer obligations for load handling. A manipulator is not just an investment in efficiency, but also in the company's legal protection.

Types of Manipulators for Various Needs

Column Manipulators

Single-joint and double-joint manipulators are ideal for:

- Stationary workstations

- Handling in limited space

- High positioning accuracy

- Applications with vertical movement

Manipulators on Travel Tracks

Manipulators on travel tracks are ideal for:

- Connecting multiple workstations

- Long handling routes

- High productivity

- Production line operation

Special Purpose Machines

Special purpose machines are designed precisely for specific applications. Maximum efficiency for minimum price.

Practical Experience from Operation

Automotive: A manipulator on travel track handles engine block transfers between workstations. One operator serves five stations instead of two.

Engineering: A column manipulator for lathe operation eliminates injury risk and increases precision. The operator focuses on quality, not lifting.

Logistics: A manipulator for loading can process double the amount of shipments with half the physical strain.

Implementation Planning

Needs Analysis

- What loads do you handle?

- How often and over what distances?

- What are the space limitations?

- What is the time pressure?

Selecting the Right Type

There is no universal solution. Each application has its specifics and requires an individual approach.

Measuring Return on Investment

Calculate not only time savings, but also reduced accident rates, fewer sick days, higher work quality, and better work morale.

Future of Classic Manipulators

While robots are being discussed, manipulators are also evolving. Modern solutions offer:

- Intelligent load balancing

- Electronic speed and position control

- Integration with industrial systems

- Predictive maintenance

What's important is that they remain what they have always been - reliable, simple, and efficient tools.

Conclusion: Practicality Wins

In an era of technological enthusiasm, it's important to keep your feet on the ground. Manipulators represent proven, profitable, and reliable solutions for most applications. Before getting carried away by visions of fully automated operations, ask yourself a simple question: "What do I actually need?"

Often you'll find that the answer isn't a robot worth millions, but a good manipulator for a fraction of the cost that will solve your problem just as effectively and with much less risk.

Manipulation technology isn't about the latest technologies. It's about practical solutions that work day after day, year after year.