07.Aug 2025

Vacuum Manipulators: How They Work and Where They Are Used

Vacuum manipulators play an irreplaceable role in material handling across many industrial sectors. Their ability to safely, quickly and efficiently move diverse objects makes them an essential tool that significantly contributes to increased productivity and workplace safety. These devices are designed to replace or significantly facilitate human labor, especially when handling heavy, bulky, fragile or difficult-to-grasp loads.

Operating Principle of Vacuum Manipulators

The basic operating principle of vacuum manipulators lies in using negative pressure to grip objects. This negative pressure, commonly called vacuum, is created by evacuating air from a closed system.

Physics of Vacuum

The purpose of vacuum systems is to generate negative pressure – that is, pressure lower than atmospheric pressure (atmospheric pressure value is typically around 1,000 millibars). In addition to vacuum level, pumping speed is also an important parameter, which indicates the volume of air that the pump can evacuate per unit of time, commonly expressed in cubic meters per hour [m³/h]. As pressure decreases, pumping speed usually decreases as well. Vacuum manipulators in practice work with various levels of negative pressure depending on the application.

Gripping Principle

Industrial vacuum manipulators operate using an arm or telescope equipped with vacuum frame with suction cups. After applying the suction cup to the object's surface, air is evacuated from its internal space, creating negative pressure (vacuum). The resulting vacuum under the suction cup essentially holds the object. This force directly depends on the vacuum value created and the area on which the vacuum acts. The vacuum gripping method is universal and thus suitable for various materials and surfaces. Moreover, unlike magnetic grippers, it does not cause secondary magnetization of metal objects.

Vacuum Generation

Vacuum for manipulators is generated in various ways:

- Pneumatic vacuum generators (ejectors)

These generators use compressed air to create vacuum. Their main advantages are short time to achieve vacuum and possibility of direct integration with the gripping element due to their small dimensions and low weight. Ejectors can also be connected in series to create multiple vacuum sources. Electric vacuum generators (pumps or blowers)

- Vacuum pumps generate high vacuum at low flow rate. Examples include oil-sealed rotary vane pumps.- Blowers enable high flow rate with relatively low vacuum value.

Electric generators offer easy integration with gripping heads or vacuum frames and often have built-in vacuum level setting function. Some models also have optional motor speed control function and electropneumatic reverse system.For energy saving, vacuum generators can automatically shut off once the required negative pressure is achieved, and restart when pressure exceeds the defined value.

- Self-priming manipulators

Some vacuum manipulators, called self-priming, operate without external power supply. The necessary negative pressure is created by the weight of the load itself, which ensures sealing between the suction cup and surface, so atmospheric pressure creates the suction effect. These types are suitable for horizontal movement of flat loads with impermeable surfaces.

When selecting a vacuum generator, it is necessary to precisely understand process requirements and avoid oversizing, which would lead to unnecessarily high energy and operating costs. Vacuum vessels or reservoirs can significantly contribute to energy savings by enabling automatic shutdown or switching the pump to idle mode once the required vacuum level is achieved in the vessel.

Components of Vacuum Manipulators

Vacuum manipulators consist of several main components that together ensure efficient and safe operation.

Suction Cups

Suction cups are one of the most important and simultaneously most sensitive and vulnerable parts of vacuum grippers. Their main task is to ensure sufficiently tight contact with the object and maintain it throughout the entire load handling period. Damage to suction cups occurs when in contact with rough, hot or contaminated surfaces.

Shapes and constructions of suction cups

- Round suction cups are suitable for handling regular-shaped objects or for assemblies with many suction cups.

- Oval suction cups are suitable for long narrow objects.

Many suction cups are equipped with bellows, which serve a dual role. They compensate for height differences when applying to objects and function as shock absorbers between the manipulator arm and object, which is important for handling delicate components.

Suction cup materials

The suction cup material must be adapted to the material of the gripped object.

- For delicate objects, soft elastomers are used.

- For wood or sheet metal, harder materials are more suitable, often resistant to elevated temperatures.

- Suction cups from special elastomers that meet standards of various industrial sectors, including food and pharmaceutical industries, and leave no marks on transported objects.

Replacement and Accessories

Suction cups are often equipped with connectors for quick replacement. This allows for faster service or replacement when handling new objects is needed. A range of accessories is also available, such as sealing profiles for rough, smooth and textured surfaces, flanges, filters, sealing inserts and support elements.

Mounting Elements and Adapters

These elements serve to integrate suction cups or special grippers with the vacuum system. They include:

- Joint, multi-directional couplings, which improve suction cup contact with uneven object surfaces.

- Spring compensators for bridging height differences and ensuring gentle lifting and lowering of objects.

Valves

Valves are essential for controlling vacuum and compressed air and their proper selection increases reliability and efficiency of vacuum systems. They could be divided into:

- Solenoid valves (controlled directly or pneumatically).

- Check valves and flow limiters for closing vacuum lines to unused suction cups.

- Control valves.

- One-way valves with spring return mechanism for system protection in case of vacuum generator failure.

- In addition to automatically controlled valves, there are also manually controlled valves for use in manual lifting devices or for emergency air flow control in automation equipment.

Filters and Fittings

The vacuum system is susceptible to suction of contaminants, whether material debris, lubricants, liquids or dust. These usually result in failure of vacuum generator, piping and valves. Filters serve to protect the vacuum system from these contaminants. Regular cleaning of dust filters is essential for trouble-free operation. For vacuum distribution in the system, manifolds, hoses, fittings and connections are used that connect suction cups with vacuum generators.

Sensors and Monitoring Equipment

For trouble-free operation and safety of the vacuum system, monitoring equipment is used that controls system status and vacuum values.

- Mechanical and electronic vacuum switches monitor negative pressure.

- Pressure sensors (with analog or digital output and display) measure pressure.

- Vacuum regulators and pressure reducing valves help maintain the required vacuum level.

- Warning devices provide acoustic and optical signaling in case of negative pressure loss, which is crucial for safety. In case of power failure, the lifted load must be maintained for at least five minutes.

- Modern pumps can be equipped with smart sensors that inform operators or service technicians in real time about upcoming maintenance, which is part of the Industry 4.0 trend.

These components together form a complex system that enables vacuum manipulators to efficiently fulfill their tasks in a wide range of applications.

Advantages and Diverse Applications of Vacuum Manipulators

Investment in vacuum manipulators proves to be very advantageous, thanks to their ability to significantly increase speed, precision and work efficiency. Companies that choose them gain significant competitive advantage. The most frequently mentioned benefit is savings in human labor. After all, one vacuum manipulator can handle the work of a large number of people, especially when handling heavy and bulky loads. This reduces physical strain on employees and minimizes the risk of accidents and health problems associated with heavy handling. Overall, it improves working conditions and increases performance. Handling vacuum equipment is intuitive, and suppliers often offer comprehensive personnel training, which facilitates their quick and efficient integration into operation.

Versatility and scalability are additional advantages. The principle of these manipulators is easily understandable and applicable. Gripping force depends on vacuum value and area on which it acts, and can be easily changed. This enables efficient transfer of both miniature components, such as watch gears or SMD electronic components, and large and massive objects, for example automotive components on assembly lines, sheets, plates or furniture elements. Unlike magnetic grippers, which can cause secondary magnetization of metal objects, vacuum grippers do not affect properties of transported objects.

Diverse use of vacuum manipulators spans across many industrial sectors:

- Construction and logistics

They serve for safe and precise lifting and positioning of heavy and fragile materials, such as windows, tiles, glass panels, sandwich panels and stones. They can be combined with mini-cranes for work at heights and in hard-to-reach places. - Manufacturing and assembly

They find application in automated processes, where they replace strenuous, monotonous and dangerous human labor. They thus contribute to reducing accidents, smoother and faster production and, last but not least, to better quality outputs. Common operations include inserting and removing objects, inter-operational handling, technological and control operations. - Food and pharmaceuticals

They are used for handling packaging, bags, blisters and films, with suction cup materials meeting strict international standards and leaving no marks on transported objects.

It can clearly be seen that vacuum manipulators represent a universal, efficient and safe solution for a wide spectrum of handling tasks in modern industry.

Safety and Maintenance of Vacuum Manipulators

Operating safety is absolutely crucial for vacuum manipulators, especially regarding handling of heavy and often fragile loads. Vacuum manipulators are designed with comprehensive safety features. One of the main features is equipment with two redundant vacuum circuits, which ensure that in case of one circuit failure, the load does not fall. Furthermore, the monitoring system includes vacuum gauges that show current negative pressure for each circuit, and acoustic warning device that activates when negative pressure drops below critical value (e.g., -0.6 bar) or when battery charge is insufficient. Vacuum reservoir with check valve additionally maintains vacuum even in case of power failure, giving operators time to safely place the load.

For safe operation, personnel qualification is essential. Operators must be authorized to handle the given equipment, properly trained and must regularly undergo safety training. Before each use, visual inspection of the equipment is necessary and it must be ensured that the load surface is clean, dry and free of any substances (such as dust, oil, moisture) that would reduce friction and thus gripping safety. Handling loads above people is strictly prohibited, and care must be taken that no persons are in the danger zone. In case of emergency situations, such as vacuum failure or leak, it is necessary to immediately inform all persons nearby and attempt to safely deposit the load.

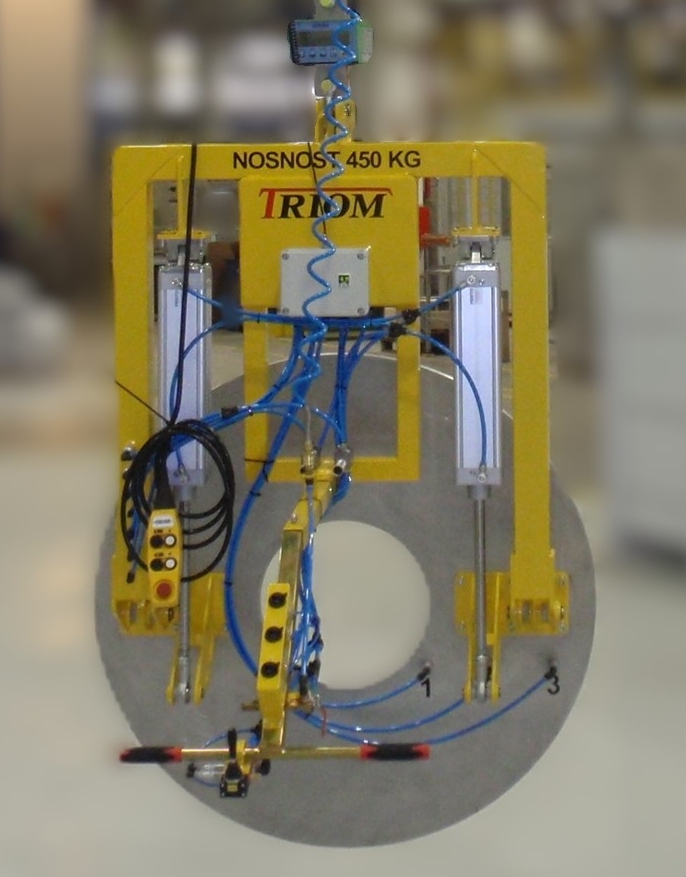

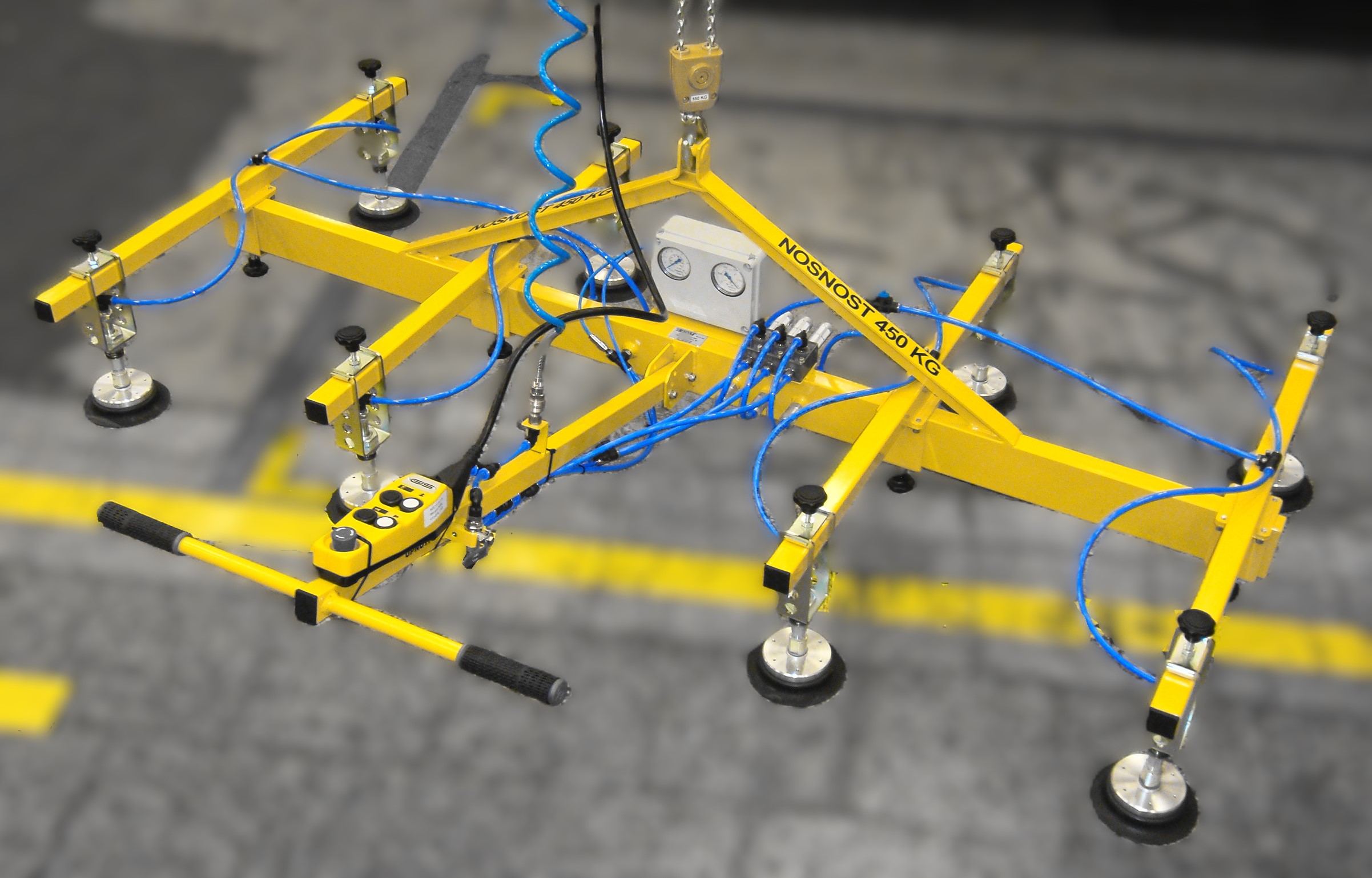

Regular maintenance is another pillar of reliability and long service life of vacuum manipulators. Reliable suppliers, including Triom, offer comprehensive service services, including installation, operator training, spare parts supply and regular inspections.

The maintenance plan includes checks with various intervals:

- Daily / Weekly

Check of gauge, warning device and battery charge status. Weekly cleaning of dust filter is also recommended, depending on environmental dustiness. - Monthly

Check of entire vacuum system tightness. Pressure drop should not exceed 0.1 bar in 5 minutes. - Semi-annual / Annual

Check of tightness of all screw connections, condition of vacuum hoses and their connections, load-bearing parts and readability of nameplate and warning signs. Replacement of dust filter cartridge is necessary at latest after 2 years or when pressure drops by 0.2 bar. Suction plates should be regularly cleaned with warm soapy water and mechanically (soft brush), and damaged or worn parts should be immediately replaced.

Vacuum manipulators should not be stored on suction plates to avoid damaging them. Compliance with these rules ensures safe, trouble-free and efficient operation of vacuum technologies.